Electrolyte solutions for electric double-layer capacitors

An electric double layer capacitor (EDLC) is an energy device that is expected to be deployed in applications such as backup power sources for portable devices, power sources used for momentary voltage drop compensation, as well as for automobiles, solar cells and fuel cells.

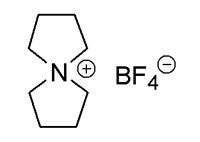

We are engaged in the production and sale of EDLC electrolytic solutions for containing SBP-BF4 (5-azoniaspiro [4.4] nonane tetrafurholoborate; a high-performance electrolyte with a characteristic structure) that has been dissolved within various solvents.

The KKE Series of electrolyte solutions using SBP-BF4 (which has a unique structure), is expected to provide higher performance and higher reliability when it comes to EDLC.

- High solubility when it comes to various solvents. (PC at 3.5 mol/L; even dissolves in linear carbonates)

- Features low viscosity and high conductivity when compared with standard quaternary ammonium electrolyte solutions.

- Features high stability in relation to electrical and thermal elements.

Due to the unique structural characteristics involved, EDLC provides reduced internal resistance, temperature characteristics, high current charge/discharge, and improvements in reliability when compared to conventional quaternary ammonium electrolyte solutions (TEA-BF4, TEMA-BF4).

*This table can be scrolled horizontally.

| Product | Electrolytic solution composition | Conductivity [mS/cm] | Remarks | |

|---|---|---|---|---|

| Carbonate type | KKE-15 | 1.5M PC | 16 (@25℃) | Standard product |

| KKE-15D | 1.5M PC/DMC | 18.5 (@25℃) | High-conductivity article | |

| Nitrile type | KKE-10TAN | 1.0M AN | 54 (@25℃) | |

| Sulfone type | KKE-20MSX | 2.0M SL/DMS | 6.6 (@25℃) | For high-pressure articles |

| KKE-15SEi | 1.5M SL/EiPS | 5.5 (@25℃) | For high pressure articles (for 3.0 V purposes) | |

Values are for reference only and do not serve as guarantees pertaining to the product.

In addition to the above electrolyte solutions, customized products can also be offered, such as those for electrolytes, electrolyte concentrations, and composition changes according to customer requirements. We also accept requests for electrolytes on a stand-alone basis.

Provision

Thanks to the automation of manufacturing facilities, we can supply electrolyte solutions with stable quality levels. In addition, we have various analysis and evaluation equipment and will meticulously handle tasks such as the analysis of defects when it comes to electrolyte solutions.

Reference standard (for KKE-15)

*This table can be scrolled horizontally.

| Conductivity [mS/cm] |

Na,K [ppm] |

Water content [ppm] |

Halogen [ppm] |

Metal content [ppm] |

|---|---|---|---|---|

| 16±1 | 100> | 30> | 5> | 5> |

Packaging (for KKE-15)

(image)

| Type | Content | |

|---|---|---|

| Canister (returnable) | 200L | 240kg |

| 100L | 120kg | |

| 18L | 20kg | |

| 1WAY Drum | 200L | 240kg |

| 20L | 20kg | |

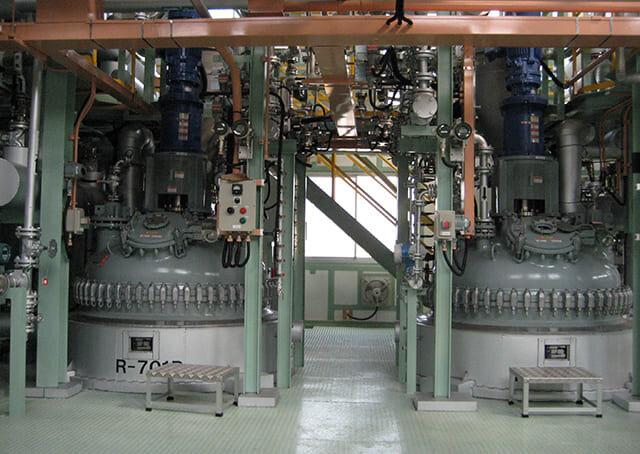

Manufacturing equipment

(electrolyte solution manufacturing equipment)

(PLC-controlled semi-automatic manufacturing)

Contact

- Carlit Co., Ltd. Electronic Materials Dept.

- 03-6685-2047

- Reception hours

- 9:00 a.m. to 5:00 p.m.

(excluding Saturdays, Sundays, national holidays and the New Year holiday)