With an eye to realizing a sustainable society, we will strive to respect the natural environment and conduct environmentally-friendly manufacturing by implementing business activities that give consideration to conserving and protecting the global environment.

Our hydroelectric power plant

Koto Hydroelectric Power Plant

Our Group's core technology is electrolysis, and securing stable electric power is essential. This hydroelectric power plant was built in 1953 by Japan Carlit Co., Ltd.(currently Carlit Co., Ltd.) in anticipation of the future power situation in Japan.

The main feature of this power plant is that it utilizes the difference in elevation of the river bottom and does not require large-scale civil engineering work like a dam.

The discharged water is also used to generate electricity at downstream power plants in Gunma and other prefectures.

The power generation structure is truly synonymous with clean energy, making effective use of renewable energy sources that do not damage the natural system.

The plant has an annual generation capacity of approximately 18.6 million kWh, which corresponds to an annual reduction of more than 8,300 tons of CO₂ emissions from an environmental perspective and a contribution of approximately ¥300 million in purchased‑electricity cost savings from a business performance perspective.

We will carefully maintain and utilize the Koto Hydroelectric Power Plant, the "treasure" of our Group, and contribute to society from an environmental perspective through environmentally conscious operations.

100% renewable energy plant/Gunma Plant

The plant began operations in 1934, mainly to produce raw materials by electrolysis.

The plant manufactures ammonium perchlorate, a raw material for solid propellants used in rockets, as well as electronic materials and related products, all of which are powered by renewable energy generated at the Koto Hydroelectric Power Plant.

A battery laboratory, which conducts charge-discharge cycle tests and storage degradation tests on batteries, is also located on the factory premises.

Clean energy supports the performance and safety of storage batteries, which are garnering attention as a sustainable energy source.

Chemical Product and Wastewater Management Initiatives

The Carlit Group & water resources

The Carlit Group's founding business was salt water electrolysis based on Tone River water rights, a foundational technology that remains central to our Chemical Products Business to this day.

This hydroelectric power described above is used to manufacture ammonium perchlorate (a basic chemical used as raw materials for solid propellants for rockets) and for next-generation battery assessment service (contract battery testing), both of which fall within the Development Area in our business portfolio.

The beverage plant in our Bottling Business (JC Bottling Co., Ltd.) manufactures beverages using abundant underground water supplied from the foothills of Mount Haruna.

However, inadequate wastewater management at our main plants (Carlit Gunma Plant and JC Bottling Co., Ltd.) located along the Tone River would risk contaminating the vast Tone River basin and adversely affecting drinking and agricultural water in the metropolitan area.

That is why we manage wastewater quality strictly while maintaining multiple spill prevention systems and conducting daily spill prevention drills to reduce the risk of environmental contamination.

Chemical management & water stress assessments

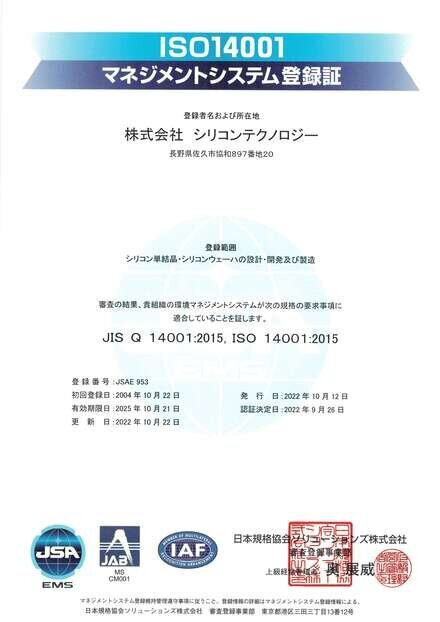

The Carlit Group has obtained ISO 14001 certification for several Group companies, and through its environmental management system, identifies potential water pollutants that could be harmful to water ecosystems and human health.

The FY2024 ISO audit detected no major issues, ascertaining the continuous and effective functioning of our PDCA cycle.

Specific methods and standards include the identification and classification of potential water pollutants in accordance with the Water Pollution Control Law, the PRTR Law, and other laws and regulations, as well as initiatives to establish manufacturing processes that do not contain harmful chemical substances in wastewater, and systems to monitor wastewater using conductivity meters and pH meters to immediately detect any leakage from plants.

We have assessed water stress at each Group location and verified that no sites currently face high water stress.

Carlit (formerly Japan Carlit Co., Ltd.) and JC Bottling are both working to protect water resources by participating in environmental conservation projects such as periodic thinning of prefectural forests in Gunma Prefecture.

Our other businesses include pyrotechnic manufacturing such as torches, silicon wafers, metal processing, and painting, which are less dependent on water resources than the two businesses mentioned earlier, leading us to identify the city of Shibukawa in Gunma Prefecture, where these two businesses are located, as a priority region.

To achieve our 2030 vision of "contributing to a sustainable society by combining the power of chemistry and technology to support people's happy lives," we will work to reduce the risk of environmental contamination through proper chemical and wastewater management while protecting water sources and sustaining water resources.

Biodiversity Initiatives

Approach

Our Group's Bottling segment utilizes coffee beans as raw materials for the production of specific products. (While this business involves contract manufacturing for customers, the coffee beans used as raw materials are sourced from Vietnam and other places.) Concerns about potential biodiversity loss due to deforestation and forest destruction associated with farmland expansion for coffee cultivation have prompted us to take action. We are committed to procuring beans in a way that aligns with our commitment to forest conservation. This commitment includes verifying the Rainforest Alliance certification of our suppliers.

ISO 14001 Certification Acquired

Several of our group companies have obtained ISO 14001 certification, and we are working to raise the bar through our environmental management system. In particular, JC Bottling Co., Ltd. and Carlit Sangyo Co., Ltd., whose business areas are related to our Gunma Plant, have obtained certification as part of the Carlit Co., Ltd. organization and have expanded the scope of their activities to engage in environmental impact assessments.

With regard to the results of the ISO audit in fiscal 2022, no significant findings were detected, and we believe that the PDCA cycle is continuing to function effectively.