History of Carlit (2013-)

- History

- Carlit's R&D History

-

October, 2013 Carlit Holdings Co., Ltd., a pure holdings company, was established through a stock transfer from Japan Carlit Co., Ltd. Listed on the First Section of the Tokyo Stock Exchange.

General Design Co., Ltd.became a subsidiary with capital participation. -

February, 2014Toyo Spring Industrial Co., Ltd.became a subsidiary with capital participation.

-

October, 2015Namitakiko Cp., Ltd. establishes a new company, Asia Giken Co., Ltd., and enters the stud business through a business transfer.

-

January, 2016Sankyo Jitsugyo Co., Ltd.became a subsidiary with capital participation.

-

April, 2016Japan Carlit Co., Ltd., Japan Abrasive Grain Co., Ltd. And Daiichi Yakuhin Kogyo Co., Ltd. Merged.(The Surviving Company is Japan Carlit Co., Ltd.)

-

April, 2022Moved to the Prime Market in accordance with the Tokyo Stock Exchange's market restructuring.

-

July, 2024Changed company name from Carlit Holdings Co., Ltd. to Carlit Co., Ltd.

-

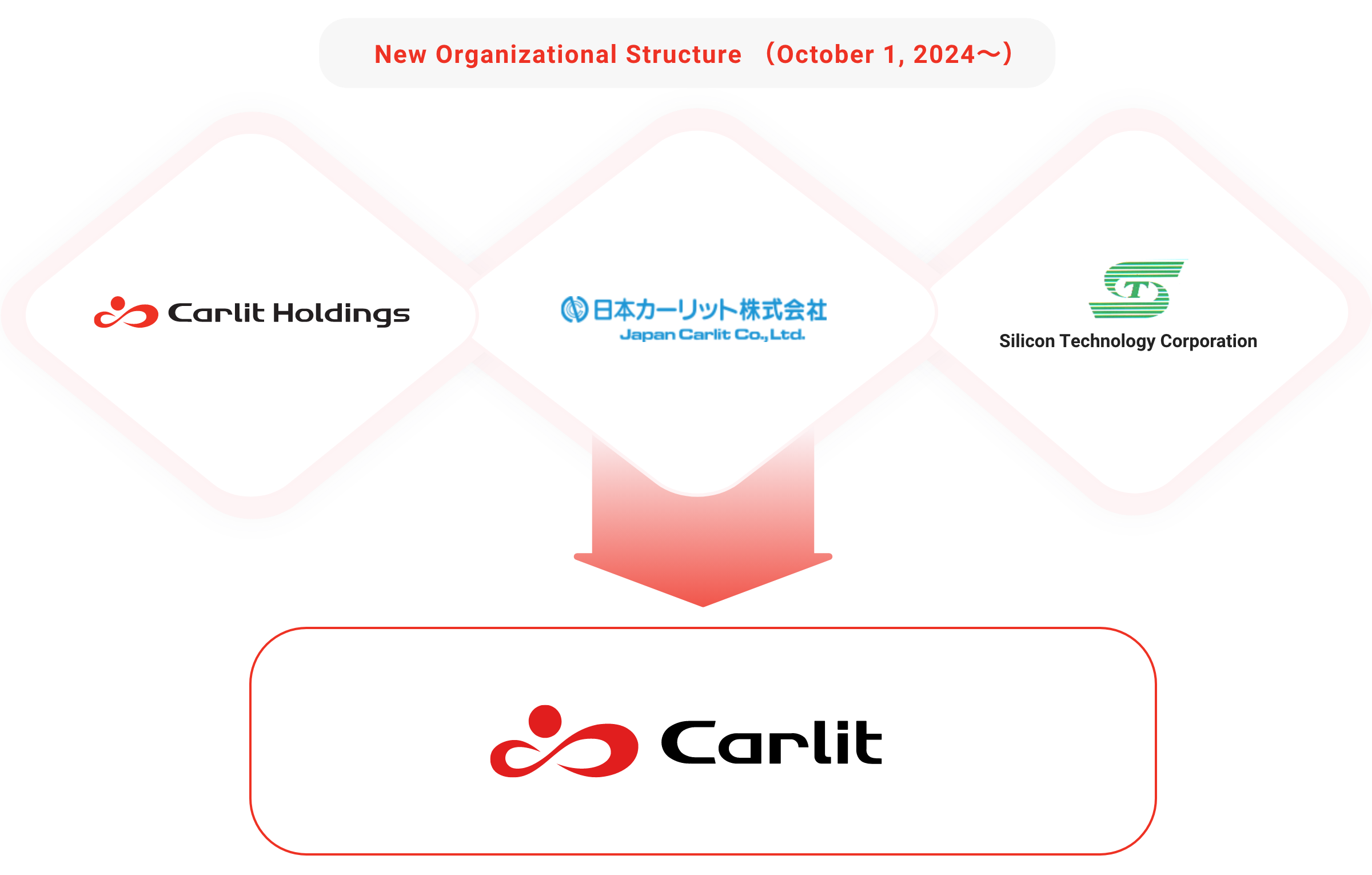

October, 2024Moved from a pure holding company structure to a business holding company, and the Company undertaked an absorption-type merger involving Japan Carlit Co., Ltd. and Silicon Technology Corporation.

| 1984 | Central Research Laboratory was established. Production of organic conductive material (TCNQ complex) launched. |

|---|---|

| 1991 | Production of UV-cut films launched. |

| 1992 | Reorganized the Central Research Laboratory into the Research and Development Center. Project of polypyrrole capacitors (PC) started. |

| 1994 | Electrical conductivity imparting agents using ionic compounds(PEL) plant was established. |

| 1995 | Production of near-infrared absorbing dyes (CIR) launched. |

| 1998 | Production of polymer solid electrolytic capacitors(PC-CON) launched. |

| 2000 | Pyrrole refining plant and electrolytic polymerization solution plant was established. |

| 2004 | A pilot plant for the spiro compound electrolyte was established. |

| 2006 | Received order from JAXA for Lithium Ejection System (LES) for thermospheric wind measurements. |

| 2007 | Production of CIR/ITO composite films launched. |

| 2008 | Electrolyte plant for electric double layer capacitor was established. |

| 2013 | As stock transfer from Japan Carlit Co., Ltd., R&D department was transferred to Carlit Holdings Co., Ltd. |

| 2021 | To increase the speed and efficiency of new product development and clarify the division of roles, R&D department was transferred to Japan Carlit Co., Ltd. |

Integration Framework

History Behind the Integration

Since October 2013, the Group has been working to strengthen its competitiveness and promote growth based on a pure holding company structure. As originally intended, the holding company structure serves to separate management from business operations and has us going about addressing management issues such as structural reform for existing businesses and the improvement of our financial structure while simultaneously striving for overall optimization from the perspective of Group management. Doing things this way has allowed us to achieve our goals to a certain extent when it came to overcoming the aforementioned issues. Having done that, we determined that the optimal course of action would be to change the organizational structure of the Group in order to facilitate the acceleration of decision-making, slim down management departments, and rebalance things in terms of personnel as part of our business infrastructure restructuring strategy, with the goal of such action being the achievement of our Vision for 2030 as outlined in the mid-term management plan ("Challenge 2024") we launched in fiscal 2022 and the improvement of PBR. Specifically, that direction would have us moving from the current pure holding company structure to a business holding company structure, which involves merging Japan Carlit Co., Ltd. and Silicon Technology Corporation into the Company, with the foundation being a focus of efforts on the business portfolio outlined in our mid-term management plan along with growth areas. By doing that and unifying our management structure, the move will have us going about promoting growth strategies and undertaking the optimization of management.

Japan Carlit Co., Ltd. (1916-2024)

- 1916-1950

- 1951-1970

- 1971-1990

- 1991-2010

- 2011 to Present

-

1916Founder Soichiro Asano obtained manufacturing and sales patents for Carlit Explosives in the Far East from Sweden Carlit and then commenced research and development at the Asano Family Company.

-

1918Established a new pharmaceutical department at the Asano Family Company and obtained a patent for Carlit Explosives in the same year.

-

1919Constructed a plant in Hodogaya Ward of Yokohama City (Hodogaya Plant) and commenced the production of Carlit Explosives.

-

1920Established the (former) Japan Carlit Co., Ltd.

-

1923Absorption-type merger into Asano Cement Ltd.

Continued business as the Carlit Division. -

1934Established Asano Carlit Ltd. (Capital: 1.5 million yen).

Took over the Carlit business after it was transferred away from Asano Cement Ltd. and a raw material plant (Gunma Factory) was constructed in Furumaki Village of Kitagunma-gun in Gunma Prefecture (with the location in question now being a part of Shibukawa City). -

1939Started production of the Sakurundum series of abrasives.

-

1942Kanto Hydroelectricity Co., Ltd. and Sekisui Kogyo Co., Ltd. were merged and the company name was changed to Kanto Electric Kogyo Co., Ltd. Took a stake in Kanto Chemical Industry Co., Ltd. (currently Kanto High Pressure Chemical Co., Ltd.), turning it into a subsidiary.

-

1945Company name changed to Kanto Electric Industry Co., Ltd.

-

1949Listed on the Tokyo Stock Exchange.

Launched the Dezorate series of herbicide.

-

1951Company name was changed to Japan Carlit Co., Ltd.

-

1953A new production facility was constructed for the high-grade bleach Silbrite on the Gunma Plant premises and commenced sale of the product.

-

1953Constructed a private hydroelectric power plant (Koto Power Plant; constant output of 3,300 kW) in Minamitachibana Village, Seta-gun, Gunma Prefecture (with the location in question now being a part of Maebashi City).

-

1956Developed a chlorine dioxide generator for pulp bleaching. (JCC Act)

-

1962New equipment for ammonium nitrate fuel oil explosives was installed at the Hodogaya Plant and commenced sales.

-

1966Constructed a new production facility for Hiflare safety flares for emergency usage at the Hodogaya Plant and commenced sales.

-

1969Toyota Delivery Center established in Toyota City, Aichi Prefecture.

-

1975Commenced sales for Hypocell, a sodium hypochlorite electrolysis generator product.

-

1976Established Japan Abrasive Grain Co., Ltd.

-

1980Established Carlit Sangyo Co., Ltd.

-

1984New organic conductor manufacturing facilities were established at the Gunma Plant. Sales are commenced for TCNQ complex, an organic conductive material.

-

1991Sales were commenced for the R Electrode product for water purifiers for home use.

Established JC Beverage Co., Ltd. -

1994Established Silicon Technology Corporation.

Launched the silicon wafer business. -

1995Constructed a product plant (Akagi Plant) in Akagi Village of Seta-gun, Gunma Prefecture (in present-day Shibukawa City) and started manufacturing gunpowder.

Hodogaya Plant closed down. -

1998Sales are commenced for PC-CON,

a polymer electrolytic capacitor product. -

1999Acquired ISO9001 certification.

-

2001Acquired ISO14001 certification.

-

2006Launched sales of Hiflare Plus Pick safety flares for emergency usage, which come equipped with glass breakers for emergency evacuation.

-

2010Established JC Bottling Co., Ltd.

Commenced the bottling business.

Established local subsidiary in Shanghai, China,

called Japan Carlit (Shanghai) Co., Ltd.

-

2011Established a local subsidiary in Singapore called Carlit Singapore Pte. Ltd. Increased the number of pieces of indoor and outdoor testing equipment to meet orders for large-scale testing involving hazard assessment tests.

-

2012Acquired a stake in and made a subsidiary of Fuji Shoji Co., Ltd., which is engaged in the paint and coating business. Acquired a stake in and made a subsidiary of Namitakiko Co., Ltd., which manufactures and sells various types of fireproof and heat-resistant hardware and pollution control equipment parts.

-

2013A battery testing laboratory was established on the Gunma Plant premises.

Carlit Holdings Co., Ltd., a pure holding company, was established as a result of a share transfer involving Japan Carlit Co., Ltd. -

2016Absorption-type merger undertaken for two companies:

Japan Abrasive Grain Co., Ltd.

and Daiichi Yakuhin Kogyo Co., Ltd.

Construction begins for the repair

and refurbishment of the Koto Power Plant. -

2018Turned Carlit Sangyo Co., Ltd. into a subsidiary.

Construction completed for the repair and refurbishment of the Koto Power Plant. -

2024Transition made to a business holding company

as the result of a merger between

Carlit Co., Ltd. and Silicon Technology Corporation.

Silicon Technology (1994-2024)

- 1994-2010

- 2011-2024

-

1994Establishment of Silicon Technology Corporation

Started as a subsidiary of Japan Carlit Co., Ltd., in Mochizuki-machi of Kitasaku-gun in Nagano Prefecture, a place with abundance nature (which later merged into another city). -

1995Start of operations

-

2002Development of power semiconductor substrate

<ST Wafer>

Inspired by a joint research project conducted with Shinshu University called "Neckless Transition-Free Crystal Growth Technology," developed a wafer with improved mechanical and burning strength. Combining the company name (Silicon Technology) and high strength (STRONG), named it the "ST Wafer" and obtained a patent for it. -

2007Introduction of the crystal pull-up furnace manufactured by Mitsubishi

Due to the solar bubble, demand for silicon wafers for photovoltaic panels increased with crystal pull-up furnaces being added in response to that. Then, with demand for solar products having settled down, contributions were made to the responses being undertaken in terms of the production of silicon wafers for semiconductors. -

2008Introduction of wire-saw slicing equipment

Efficiency improvements achieved for the production of thin silicon wafers for photovoltaic panels. Using wire to perform the work (slice cutting, which had been previously conducted using a conventional plate-like inner peripheral blade) allows for a reduction in the amount of silicon that ends up becoming scraps (resulting from cutting), thereby contributing to the reduction of material loss to less than half of conventional ones.

-

2013The Company became a fully-owned subsidiary of

Japan Carlit Co., Ltd. -

2014With the establishment of Carlit Holdings Co., Ltd.,

the Company became a fully-owned subsidiary of

Carlit Holdings Co., Ltd. -

2017Development of optical materials for

far-infrared rays <HT Silicon>

Conducted collaborative research with the R&D Center to develop optical materials suitable for far-infrared devices such as thermography and night surveillance cameras. -

2018Launch of the germanium refining business

The Company started a business involving the refining of germanium to high-purity germanium using a method called the Zone Melt Method, which entails using germanium dioxide and processed end materials as the starting materials. The Company became the only germanium refiner in Japan by selling the product as a raw material for alloys and organic germanium. -

2019Celebrated the 25th anniversary of the Company's founding.

-

2021Launched a business for the manufacturing of

ultra-high flatness wafers

The introduction of high-precision grinding equipment resulted in the improvement of the accuracy of wafer surface flatness processing to 1 μm or less (overcoming a 3 μm wall) and the establishment of the product as a wafer for substrates used in MEMS (microelectromechanical systems). -

2024Moved from a pure holding company structure to a business holding company, and the Company undertaked an absorption-type merger involving Japan Carlit Co., Ltd. and Silicon Technology Corporation.