Our electrode technology, developed over more than 60 years across various fields, has been instrumental in enhancing the processing capacity, safety, and stability of various devices and systems. As demands for higher efficiency and durability in insoluble electrodes continue to grow, we remain committed to further technological improvements and developments, constantly challenging new frontiers.

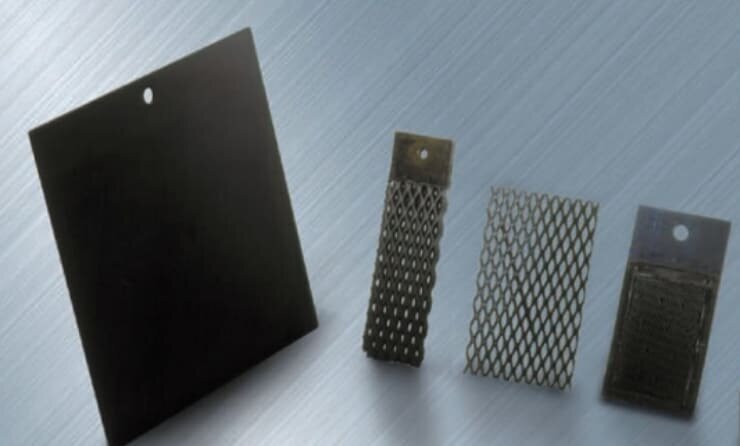

Insoluble metal electrodes

The "Excerode Series" metal electrodes, which feature a precious metal catalyst layer coated onto titanium, are used in various applications. These include seawater electrolysis systems for preventing marine organism adhesion on seawater lines, hypochlorous acid water generators using tap water, plating applications, and surface treatment fields. Our group company, Carlit Sangyo Co., Ltd., also markets the "Hypocell Series" of seawater electrolysis systems and brine electrolysis sterilization devices. The electrodes and electrolysis technology we provide are highly regarded for their reliability and safety, and are widely adopted across various sectors.

Excerode

We will continue to meet the diverse needs of our customers based on our in-house knowledge and technical capabilities when it comes to electrolysis.

History of the Excerode Series

1970 Onward

-

The Company has used magnetite electrodes for the electrolysis of salt. Around 1970, the Company introduced insoluble electrode technologies from overseas and succeeded with in-house manufacturing. Since then, we have been using our own insoluble electrodes at our electrolysis plant.

1980-1990

-

In addition to in-house use, electrodes have been developed for various applications. We offered the product to the market in the form of the Excerode Series and began the sale of electrodes.

We offer electrodes that are ideal for applications such as metal recovery, precious metal plating, wastewater treatment, seawater electrolysis, salt water electrolysis, and ionized water.

Fired electrodes

Excerode [R/RN Type]

Excerode R/RN consists of electrodes formed by means of the pyrolysis (firing) of a platinum-based coating layer on a titanium substrate. While electrodes produced by means of the conventional pyrolysis method could not be used as cathodes, Excerode R and RN can also be used as cathodes, enabling energization by means of counter-electromotive force. This prevents scale adhesion when it comes to water splitting, etc., and allows for continuous operation to take place without maintenance for long periods of time.

*This table can be scrolled horizontally.

| Name | Coating material | Electrolytic region | Counter-electromotive force compatibility | Primary application(s) | Standard film thickness | Standard current density |

|---|---|---|---|---|---|---|

| R-2000 | Platinum | Chlorine generation Oxygen generation |

Yes | Water electrolysis (alkaline ionized water) Dilute salt water electrolysis/Various kinds of plating |

About 0.2 μm [0.1-1 μm] |

About 1A/dm² [Up to 2A/dm²] (Water electrolysis)5-15A/dm² (Salt water electrolysis) |

| R-2500 | ||||||

| RN-2000 | Platinum composite | Chlorine generation | Yes | Water electrolysis (lowest oxidization state occurrence) Dilute salt water electrolysis |

||

| RN-3000 | Water electrolysis (alkaline ionized water/lowest oxidization state occurrence) |

Excerode [B/F Type]

Excerode B/F is an electrode formed by means of the pyrolysis (firing) of an iridium dioxide-based coating layer on a titanium substrate. Compared to lead-alloy electrodes, which have been used as anodes for oxygen generation in the past, these electrodes are extremely durable against oxygen. Since they are non-lead electrodes, there is no contamination of the liquid by lead, and no sludge is generated, so no adverse effects on the product arise. Since the electrode is used in the oxygen generation region of solutions containing sulfate, it is useful as an insoluble anode for electroextraction, electrolytic refining, and large plating lines. It is also useful as an anode for noble metal electroplating and so on.

*This table can be scrolled horizontally.

| Name | Coating material | Electrolytic region | Counter-electromotive force compatibility | Primary application(s) | Standard film thickness | Standard current density |

|---|---|---|---|---|---|---|

| B | Iridium Dioxide | Oxygen generation | No | Various plating/electrowinning Metal recovery |

About 20g/m² [10-40g/m²] |

About15 A/dm² [Up to 50A/dm²] |

| F | Iridium-based composite |

We also have another series Excerode F products that is specialized in terms of durability. Please feel free to consult with us.

Excerode [C Type]

Excerode C is an electrode made through the pyrolysis (calcination) of a ruthenium-based composite coating layer that has been blended to effectively generate the advantages of each component on a titanium substrate and to sufficiently compensate for the disadvantages. Since its chlorine generation potential is extremely low when compared with the conventional platinum electrode, and because it features excellent performance and durability, it has been incorporated into our salt water electrolytic sodium hypochlorite generating device (called Hypocell). An extensive track record has been established in that respect.

*This table can be scrolled horizontally.

| Name | Coating material | Electrolytic region | Counter-electromotive force compatibility | Primary application(s) | Standard film thickness | Standard current density |

|---|---|---|---|---|---|---|

| C | Ruthenium-based composite material | Chlorine generation | No | Production of highly concentrated sodium hypochlorite/chlorate | About 15g/m² [5-30g/m²] |

About 15A/dm² [Up to 30A/dm²] |

Excerode [S Type]

Excerode S is an electrode formed by means of the pyrolysis (firing) of a platinum-based composite coating layer on a titanium substrate. When compared with platinum-plated electrodes, ruthenium-based electrodes and palladium-based electrodes (which have been used as anodes for seawater electrolysis), it offers superior durability and is characterized by high electrolysis efficiency levels at low temperatures and low tank voltage, which means that sodium hypochlorite can be efficiently obtained with low levels of power consumption. They can also be used as electrodes for wastewater treatment.

*This table can be scrolled horizontally.

| Name | Coating material | Electrolytic region | Counter-electromotive force compatibility | Primary application(s) | Standard film thickness | Standard current density |

|---|---|---|---|---|---|---|

| S | Platinum composite | Chlorine generation | No | Seawater electrolysis/wastewater treatment | About 15g/m² [5-30g/m²] |

About 15A/dm² [Up to 30A/dm²] |

Electroplated electrodes

Excerode [BA/EA Type]

Excerode BA/EA are electrodes in which platinum is coated on a titanium substrate by electroplating. The platinum electrodes are anode materials that have been used since the beginning of the electrolysis industry. They are used in applications such as the production of perchloric acid requiring high levels of oxidation potential, electric corrosion protection, seawater electrolysis, electroplating, organic electrosynthesis, and wastewater treatment. The creation of a special intermediate layer results in improved adhesion and increased durability when compared to conventional platinum-plated electrodes.

*This table can be scrolled horizontally.

| Name | Coating material | Electrolytic region | Counter-electromotive force compatibility | Primary application(s) | Standard film thickness | Standard current density |

|---|---|---|---|---|---|---|

| BA | Platinum | Chlorine generation Oxygen generation |

Yes | Seawater electrolysis/Ionized water manufacturing Various kinds of plating |

About 2μm [1-7μm] |

About 15A/dm² [Up to 30A/dm²] |

| EA |

Excerode [LD Type]

Excerode LD is an electrode formed by means of the electrodeposition of a lead dioxide coating layer. In the past, many lead alloy electrodes had been used as anodes for oxygen generation, but that had resulted in high amounts of lead elution and ended up serving as the cause of sludge. However, this electrode hardly results in any sludge because the amount of elution is small. Due to its high levels of oxygen overpotential, Excerode LD provides exceptional durability as an electrode used for chromium plating, as an anode used for wastewater treatment equipment and ozone generators deployed for the purpose of removing COD.

*This table can be scrolled horizontally.

| Name | Coating material | Electrolytic region | Counter-electromotive force compatibility | Primary application(s) | Standard film thickness | Standard current density |

|---|---|---|---|---|---|---|

| LD | Lead dioxide | Oxygen generation | No | Hexavalent chromium plating/Wastewater treatment/Ozone generation/Organic electrolysis | About 18,000g/m² [About 1mm] |

About 15A/dm² [Up to 30A/dm²] |

Fields of application

Fired electrode/electroplated electrode

*This table can be scrolled horizontally.

| Name | For ionic water | For sterilization | For salt water electrolysis | For seawater electrolysis | Water electrolysis (without inversion) | Plating | Electrolytic cleaning | Metal recovery and refining | For wastewater treatment | For ozone generation | For cathodes | For power supply | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alkaline ionized water | Acidic water | For drinking water | Dilute sodium hypochlorite solution produced by the electrolysis of salt water |

General plating | Copper foil production | Trivalent chromium Cr | Hexavalent chromium Cr | ||||||||||

| BA | ○ | ◎ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ◎ | ○ | ○ | ||||

| EA | ○ | ◎ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ◎ | ◎ | ◎ | ||||

| R-2000 | ○ | ◎ | ◎ | ||||||||||||||

| R-2500 | ◎ | ○ | ○ | ||||||||||||||

| RN-2000 | ◎ | ○ | ◎ | ◎ | ○ | ○ | |||||||||||

| RN-3000 | ◎ | ○ | ◎ | ◎ | ○ | ○ | |||||||||||

| B | ○ | ○ | ○ | ○ | ○ | ○ | |||||||||||

| F | ◎ | ◎ | ◎ | ◎ | ○ | ◎ | |||||||||||

| C | ◎ | ○ | |||||||||||||||

| S | ○ | ◎ | ◎ | ||||||||||||||

| LD | ○ | ◎ | ○ | ◎ | ◎ | ||||||||||||

Contact

- Carlit Co., Ltd. Chemicals Dept.

- 03-6685-2046

- Reception hours

- 9:00 a.m. to 5:00 p.m.

(excluding Saturdays, Sundays, national holidays and the New Year holiday)

Redirected to the Japanese Site

Electrolyzers (Hypocell)

- Chlorine dioxide production equipment

When it comes to electrolysis equipment, a group company of ours called Carlit Sangyo Co., Ltd., has a system used for sterilizing drinking water in the fields of water purification plants and food, and a system for preventing the adhesion of marine organisms. We design and deliver manufacturing equipment to pulp and paper production businesses for bleaching that is undertaken using chlorine dioxide.

See here for the plant-relatedbusiness of Carlit Sangyo Co., Ltd.

Available in Japanese only